Product quality improvement in manufacturing using Machine Learning and Stochastic Optimization

The Manufacturing Industry relentlessly seeks to reduce costs without compromising quality. To do this it is imperative that production and the parameters associated with it, be mathematically understood and controlled. A precise understanding allows manufacturers to use intelligent recommendations for improvement on a continuous basis and realize cost savings, improve quality and unlock several other benefits. An engagement with a paper/paper board manufacturer, where ITC Infotech was required to reduce the cost of manufacturing while maintaining quality and customer acceptance parameters, resulted in the reduction of raw materials (pulp) used. The engagement also provided clear insight on operational parameters influencing paper quality. The interventions and outcomes could apply to several other manufacturing processes across industries.

Resolution

Paper is produced by pressing together moist fibers of cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets. It is a versatile material with many uses including writing, printing, packaging, cleaning, decorating, and a number of industrial and construction processes. It is characterized by properties like caliper (thickness in µm), GSM (grams per square meter) and moisture content (%) which determine properties like stiffness (ability for a sheet of paper to resist bending), bulk (weight per unit volume), tensile strength (maximum stress to break a paper sheet), edge wick (water absorption at the edge) and many others. ITC Infotech established the statistical relationship between moisture content and operational parameters using regression model. Once established and validated, the model parameters operating limits to achieve a specific range of moisture was arrived at by Stochastic Optimization algorithms. These algorithms were implemented during the production process.

Approach and Solution

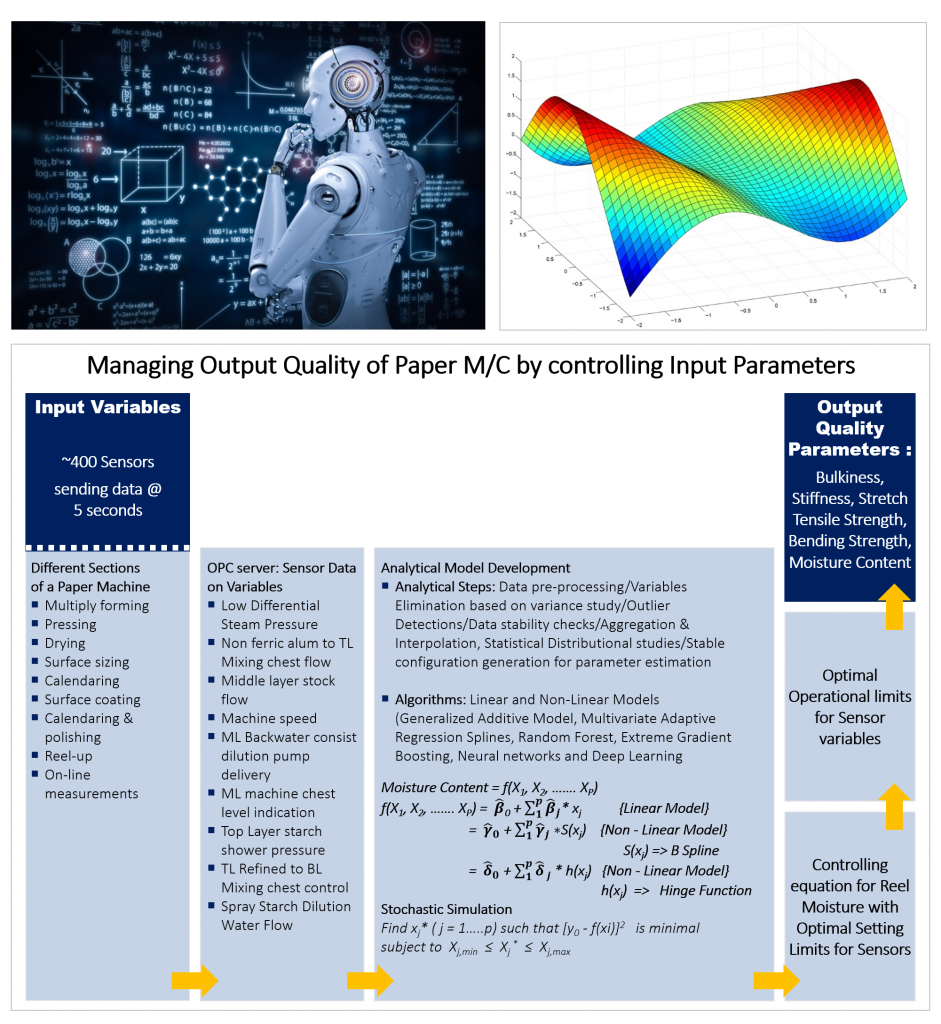

The methodology used can be broadly summarized as business understanding of the production process, data understanding, data pre-processing, data quality checks, data munging and analytical dataset preparation, model development and validation, and model parameter optimization. The objective of the customer engagement was to identify the optimal operating ranges of operational parameters significantly impacting end product moisture content, thus enabling the end users to save on multiple costs.

Reel Moisture was modelled as the dependent variable whose behavior would be explained by several sensors capturing real time information on differential steam pressure, stock flow and machine speed (to name a few of the parameters). For each paper grade, various models were developed viz. Multiple Linear Regression, Multivariate Adaptive Regression Splines, Generalized Additive Model, Neural Networks and Support Vector Machines. These established the mathematical relationship between Reel Moisture and Sensor Variables.

Once a particular model was finalized for a given product, the operational parameters that had a significant influence on the end product, the operational ranges, i.e. the range in which the particular operating parameter needs to be maintained to realize a desired percentage of Moisture Content consistently, were determined using Stochastic Optimization through genetic algorithm. For a given desired range of output of Moisture Content percent, the corresponding ranges for the operational parameters was determined iteratively. These mathematically arrived ranges of the controlling variables were then implemented on a real time basis on the paper machine and the outcome was found to be in consensus with the expected range of Moisture Content percent.

Paper manufacturing machines and associated processes

Implications

The impact of operational parameters on the moisture in the end product was statistically proven and the operational ranges prescribed had a profound impact in restricting/controlling the moisture percentage in the pre-defined range. The cost savings realized by the business in terms of reduction in steam consumption and material saved (pulp) had been proven in the trial phase. The business continues to use the recommendations, and this is a testimony to the efficacy of the solution.

Moisture Content Percentage model development process and control equation for the recommendation of operating limits of the sensors

Savings resulting from the implementation

The recommended control limits of the relevant sensor variables, when implemented in a single machine producing 5 different paper grades covering 70% of total production, was able to save approximately $0.85M in one year. An extrapolation of the savings across all the plants and machines would amount to a significant saving.

Future direction

A straightforward extension of our solution is to achieve a “Golden Batch” production state—a state where the production process is capable of generating consistent end products with respect to all the essential/critical quality parameters. In this case the parameters would be GSM, Caliper and Stiffness apart from Moisture Content. To achieve this, controlling the equation for each critical metric to be mathematically modelled as a function of different sensor variables along with the study of interdependence structure of the set of critical quality variables is necessary. Once this is done, a multi-variate Stochastic Optimization setup would generate the vector of recommended operable control limits for sensors to achieve a near Golden Batch state.

The solution is generic enough to be considered for any production process, not only limited to Paper and Paperboard Manufacturing. Among the many other useful applications, one would be to model defects in production run to minimize Cost of Poor Quality. This would be applicable across industries.

Author:

Anindya Neogi

GM, Chief Data Scientist, Digital Experience

Nikhil Dodecha

Senior Principal Consultant, Business Consulting Group