Efficient way to tanker fuel using a mathematical optimization model

Designing an analytical approach to optimize “tankered fuel” with minimal impact on fuel burn rate to reduce operations cost.

The Challenge Faced by the Airline Industry

In our previous blog, it was established that fuel costs contribute, on an average, 25%-30% of airline operations costs. In this regard, one of the key focus areas is fuel procurement. At the fuel procurement stage, airlines have at least two industry practices to focus upon:

- Secure fuel supply at minimum price possible by hedging (a medium/long-term activity)

- Procure maximum fuel possible at the lowest price possible by tankering (a tactical activity)

Conventional fuel tankering is purely based on fuel-price differential across airports. However, a more comprehensive approach is needed since fuel tankering is dependent upon multiple factors such as fuel burn, aircraft specification, weight distribution, flight path traversed, and weather information (for instance, wind speed and direction), etc. Such diverse factors make estimation of fuel tankering, on a near-real time basis, a challenging task, one that hinges upon integration of data from diverse source applications – both internal & external.

In the current context, the primary objective is to estimate optimal quality of fuel, intertwined to procurement cost, basis the (optimal) utilization of fuel across different costs, to optimize overall network cost, leading to minimal wastage, if any.

Understanding the Current Industry Landscape

Let us first understand the industry landscape in terms of fuel tankering as a phenomenon, by glancing through a few numbers. In the ECAC (European Civil Aviation Conference) area, full tankering could be performed on 16.5% of flights (on per-year basis), whereas partial tankering could be performed on 4.5% of flights. In more than 10 million flights annually in ECAC, the estimation is that 2.1 million perform fuel tankering. The breakup is as follows: 1.6 million flights (16.5%) perform full tankering and 0.45 million (4.5%) perform partial tankering. In practice, full tankering is performed on 15% of flights.

Fuel tankering would represent 136 KG of additional fuel burnt per flight concerned (costing €75), generating 428 KG of additional CO2 (i.e. 9€ in purchased CO2 allowances). In spite of the added cost, on average, fuel tankering can result in a net saving of €126 per flight. Having said that, it is extremely important that fuel supply is optimized through efficient tankering strategy, while ensuring optimal emission so that environmental policies are not violated.

How Technology can Lead the Way

With advancement in technology, a fuel tankering system or application may get integrated into flight planning system, such as ITC Infotech’s Flight Planner, which would help fuel tankering decision on a real-time situation, based on multiple parameters. It will have capabilities to simulate hundreds of scenarios based on flight path, fuel usage, weather conditions, weight and balance, etc. Hence, the tankering solution must be designed using a scalable algorithm, which can generate insights on a real-time basis, and contribute to an optimal flight plan construct.

The Solution

Since there are fuel price variations across stations, airlines tanker more fuel from departure station to minimize supply cost. However, additional fuel results in additional weight leading to high burn rate. Keeping in mind aircraft specifications and airport rules, a non-linear optimization framework has been designed with following dimensions being included in the solution.

- Maximum takeoff weight/maximum landing weight

- Fuel capacity of the aircraft

- Regulatory norms of fuel uptake in different airport stations

- Fuel benchmark based on historical flight patterns

- Engine operating efficiency

The objective is to minimize total fuel supply cost across different stations for all the aircraft flying in different rotations. Essentially, that narrows down our entire approach to the following inequality:

Let us introduce a few mathematical notations at this point to formulate the problem into a solvable equation.

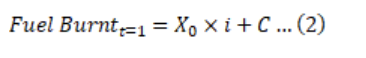

At time point t=1,

At time point t=2,

Using mathematical induction, we can derive that

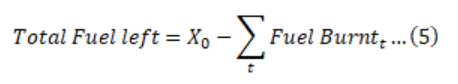

So total fuel left can be calculated as:

Replacing equation (5) in equation (1), we achieve the objective function of our optimization solution suite. Coming to operational constraints for the current optimization, here are the key boundary conditions in the process of designing the optimal solution.

Different sets of data that are considered while designing the solutions are as follows:

- Block-hour information for the entire network

- Maximum takeoff weight and maximum landing weight

- Maximum fuel capacity of the aircraft

- Passenger demand forecast

- Cargo load and estimated weight

- Weather information

- Fuel consumption planning information

- Airport policies in terms of fuel reserve and fuel uptake

We designed the problem into a multi-objective optimization framework where the objectives are to minimize supply fuel cost, and at the same time, minimize leftover fuel at the end of each rotation. We used differential evolution algorithm to solve the optimization problem. Tuning of individual parameters in DE was trained using Genetic Algorithm/Simulated Annealing. For individual passenger demand forecast framework, an ensemble approach combining regularized regression and Extreme Gradient Boosting (XGB) followed by a stacked RNN (GRU) was used.

Business Benefits

In our assessment and experience, predictive-analytics-based optimization approach in tankering could lead to 2.5%-2.7% potential cost savings. This is above the industry benchmark of 1%-1.5%.

A what-if simulator, designed and integrated with the tankering optimization solution, helps the business user, in this case Flight Ops team, to simulate scenarios and adopt the best tankering strategy – one based on not just fuel price fluctuations, but also changes in other key parameters.

Recent Posts

Enterprise Architecture Reimagined: Exploring its Facets in the AI Epoch

Enterprise Architecture Reimagined: Exploring its Facets in the AI Epoch Why organizations using DevOps tools are getting ahead of the rest

Why organizations using DevOps tools are getting ahead of the rest Generative AI: Creating the lightning rods for success (around a 3A Axis)

Generative AI: Creating the lightning rods for success (around a 3A Axis) Generative AI, a new catalyst for D2C expansion

Generative AI, a new catalyst for D2C expansion How to Maximize Business Productivity with Gen AI?

How to Maximize Business Productivity with Gen AI?